Dominion Energy

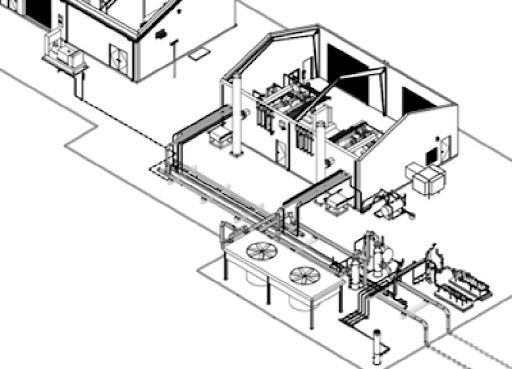

Charleston & moore compression station

Momentum staff provided the greenfield design, procurement, project management, construction management and on-site commissioning/start-up support for the installation of five (5) inline Solar Mars turbine units.

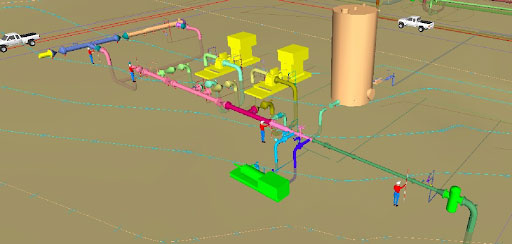

Kinder Morgan

palmetto pipeline facilities

Momentum staff provided project management, engineering and design services for the installation of support facilities for a new 360 mile long refined products pipeline transporting gasoline, diesel and ethanol. Facilities included pump stations and support facilities located in three states.

Scope of Work included equipment specifications, procurement support of buildings (warehouse/office, garage, restroom, electrical communications), 7 product tanks (4 gasoline, 3 diesel) ranging from 100,000 BBL to 150,000 BBL, meters, MOV’s, and an EDCC.

Additional tasks included the design, site preparation, containment system modifications, and drainage plans for the new facilities, as well as confirming available local utility systems. Also provided were specifications of all required process and utility equipment for ESD systems, individual tank pumps and associated manifolds and metering facilities.

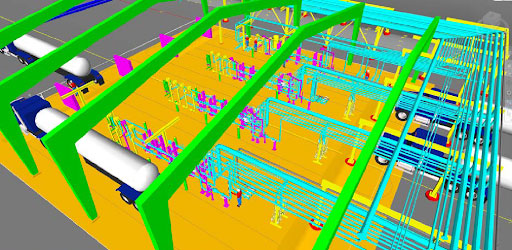

Kinder Morgan

belton terminal expansion

Momentum staff provided project management, engineering, and design services for the expansion of a pipeline terminal, including a new 80,000 barrel tank and additional rail offload for ethanol storage, as well as a new eight inch transfer line.

The existing ethanol rail offload was expanded to add spaces for another 20 cars, including the all rail infrastructure with containment, safety equipment, and pump capacity upgrades.

Scope of Work also included: composing performance specifications and assisting with procurement of railcar expansion, storage tank and electrical switchgear/MCC, 4-bay truck loading station, four new buildings, 6 new tanks, VRU system for the terminal/truck loading, fire and gas safety system for the terminal, ethanol blend skid, evaluating utility systems, modifying containment and drainage systems, and specifying equipment including: railcar offload pumps, transfer pumps, manifolds, and meters.

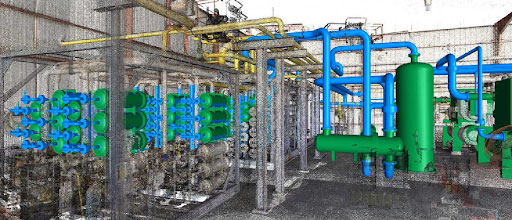

River Birch Landfill

louisiana

Momentum Staff provided engineering, design, procurement, project management, programming, construction management, and onsite commissioning/start-up support for the installation of an 8,000 scfm landfill gas recovery system and full HSE audit.

Scope of Work included equipment specifications, installation of landfill well, blowers, H2S removal unit, CO2 removal unit, pipeline compression and metering station, utilities (condensate, instrument air, used oil flare system, blowdown).

Momentum Staff provides operating services, maintenance services, and facility planning.

St. Mary Sugar Co-op

Momentum personnel has provided all controls and automation for St. Mary Sugar Mill. Before becoming involved, the only automation at the mill was on small OEM provided pieces of equipment. All mill controls were performed manually using plant personnel. Over the course of our involvement, the mill has become fully automated.

The five primary areas of the mill are cane unloading, the mill floor, the boiler room, the pan floor, and sugar fabrication. All of these areas are now fully automated using multiple Allen-Bradley PLCs and Wonderware HMIs spread across three autonomous control rooms.

Scope includes control system design assistance such as networking and communications, all PLC programming, all HMI programming, commissioning, startup support, and ongoing support during grinding season.

Devil's Tower

Momentum personnel has provided all top sides safety system design and programming for every sub-sea well since first oil in 2005. Scope includes safety system and logic diagram design, control panel design, remote I/O and junction box design, wiring diagrams, material specification, shop testing, FAT, site commissioning, startup support, and ongoing support. Additionally, support and programming were provided to integrate with the platform safety system (HIMA) and process control system (DeltaV). We have provided these services for the following subsea wells:

- Triton I

- Triton II

- Goldfinger I

- Goldfinger II

- Basslite

- Kodiak

- Kodiak II

- Southwest 1

- Southwest 2

- Southwest 3

- Walter

- Taggert

- Triton I

- Triton II

- Goldfinger I

- Goldfinger II

- Basslite

- Kodiak

- Kodiak II

- Southwest 1

- Southwest 2

- Southwest 3

- Walter

- Taggert

Regulatory and compliance submissions are also part of Momentum’s scope.